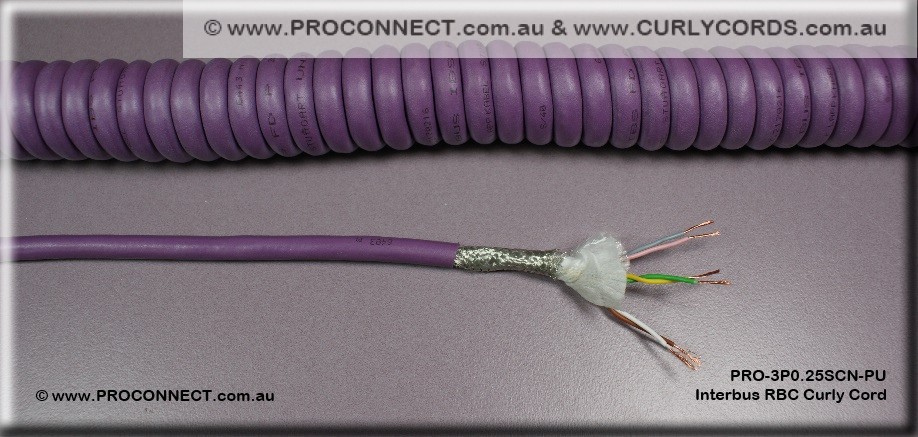

We are now able to produce INTERBUS curly cords.

Remote Bus Cable (RBC)

Suitable for highly flexible applications frequently moved machine parts instead of using power chains or cable tracks.

These cords can of course be used for a variety of other application.

Construction:

- 3 twisted pairs

- 100 Ohm Characteristic Impedance

- 60 nF/km mutual capacitance at 800Hz

- 0.25mm²

- Braid Screen

- Polyurethane sheath 7.9mm nominal

Coil Lengths include:

- 300mm

- 500mm

- 1000mm

- 1200mm

- 1300mm (may have in stock…please email to confirm)

- 1500mm

- 1800mm

- Custom coil lengths made to order (MOQ’s apply)

Straight tail length:

- 150mm

- Custom tails lengths made to order (MOQ’s apply)

Note: Unless specifically indicated, all curly cords are supplied UNTERMINATED.

Remember: we have an extensive range of connectors, and wiring accessories.

Please ask us about these as well.

Hi There,

I am looking for a cable that I need to fix to a moving glass sliding screen, it travels a distance of 680mm. The cable is used to connect to a sensor that is fixed to the moving glass screen.

I am after a cable that can connect to this sensor, we require 4 core 92 wires for 24vdc and 2 wires for 5vdc).

Do you have or can you recommend a cable for this operation? I have been looking at the interbus cur;y cord, would this suit?

The lengths shown here, 300mm , 500mm what length do they stretch too?

Thank you.

Hi Shane,

I just sent you an email.

Best regards

Paul.

Hi there,

Can you do a standard size telephone cable but in this purple colour? I’m looking for a funky telephone cable.

https://www.curlycords.com.au/wp-content/uploads/2013/05/PRO-3P0.25SCN-PU-1a5.jpg

Cheers

Hi Jennifer,

Sorry…no.

We only have “standard” colours.

I have them listed here: https://www.curlycords.com.au/curlycords/telephone-curly-cords/

Hi need one of these cords for a massage chair wiring. When the coil is compressed it measures 130mm but I have the space in the machine to store excess cable if that’s too small.

Hi Daniel,

I’m sure we can help you.

We will need more information please.

I’ll need to know the details on the cable.

i.e. How many cores are inside it, what sort of conductor size etc. – if we are lucky there might be some printing on the side that may help.

Are you able to reuse the old connectors?

Maybe some pictures might help?

Standing by….

Paul.